Conax Sealing Glands

If you need a feedthrough for temperature probes, thermocouple wires, electrodes, transducer wires or power wires passing through a pressure or vacuum wall, Conax will have a solution.

Thermal Detection Ltd is the UK distributor for Conax Technologies Sealing Glands, Feedthroughs and Fittings and we have a 20 year history of helping customers choose the right gland. Contact us today for assistance.

Overview

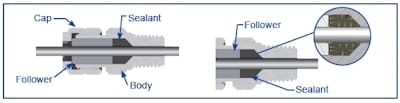

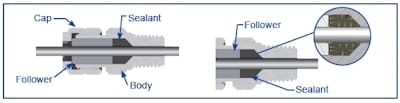

Conax Technologies Sealing Glands are based on soft-sealant technology whereby the plastic deformation of a sealant material within a fixed housing forms a high integrity seal. The standard sealant materials in use are Neoprene, Teflon, Viton, Lava and Grafoil which give different sealing capabilities across a wide range of temperatures, pressures and environments.

The glands are designed to enable easy installation, adjustment and replacement of elements. The soft sealant technology also allows repeated use of the gland simply by replacing just the sealant itself.

By carefully selecting gland type, body material, sealant material and process connection (i.e threaded, welded, flanged) it is possible to meet the requirements of many applications across all industries, and enable the sealing of pressures from full vacuum up to 670 bar (10,000 psi) and temperature ranges of -240°C to +1650°C (-400°F to +3000°F).

Standard Sealant Properties:

Sealant

Type |

Temperature

Range |

Vacuum

Rating |

Electrical

Resistivity |

Impermeability

to Gas |

Material

Features |

Neoprene

(Chloroprene) |

-40°C to 93°C |

0.005 microns |

GOOD |

GOOD |

Has resilience of natural rubber, with better resistance to oil, gasoline, ozone, weather and heat. Excellent memory for temperature cycling applications, moderate electrical resistivity, reusable in most cases. |

|

|

|

|

|

|

Viton®

(Fluorinated Hydrocarbon) |

-20°C to +232°C |

0.005 nicrons |

GOOD |

EXCELLENT |

Retains mechanical properties at high temperature. Resistant to oils, solvents, fuels, corrosive industrial chemicals. Good electrical properties, reusable in most cases. |

|

|

|

|

|

|

Teflon®

(PTFE) |

-185°C to +232°C |

0.005 microns |

EXCELLENT |

GOOD |

Most versitile elastomer material, near inert to almost all industrial chemicals and solvents. |

|

|

|

|

|

|

Lava

(MgO.Al2O3.SiO2) |

-185°C to +870°C |

Not recommended for vacuum |

GOOD |

POOR |

Excellent in high temperature, crushes to powdered mass under compression, porous to light gases and steam. NOT RECOMMENDED FOR HIGH VACUUM. Not reusable |

|

|

|

|

|

|

Grafoil®

(Graphite in foil layers) |

-240°C to +495°C

to +1650°C in non oxidising atmosphere |

0.005 microns |

POOR |

EXCELLENT |

Low vapour pressure, low gas permeability excellent for vacuum applications. Natural lubricity, electrically conductive. Superior sealing capabilities at +495°C. Not reusable in most cases. |

The main gland types are below, with links to product pages:

PG: Feedthrough gland for a single element (e.g thermocouple or RTD temperature probe) in range of imperial and metric sizes.

MHC: Feedthrough gland for sealing multiple elements (e.g thermocouple or RTD temperature probe) through a single gland.

MHM: Feedthrough gland for sealing multiple elements with different diameters through a single gland.

PGS SPG SPGA DSPG Split Glands: Feedthrough glands with split Internal components to allow installation on single and multiple elements with large diameter tips (e.g temperature probe with bulb)

EG/EGT: Feedthrough gland for single electrodes. EGT for use up to 8KV / 525A.

PL: Feedthrough gland for insulated power leads and thermocouple wires to for example, autoclaves, transformers, motors and heaters.

TG: Feedthrough gland for sealing multiple bare wires, e.g bare wire thermocouples, strain gauges, and thermistors.

TG24T/F : Feedthrough gland with factory installed thermocouple wires with either Teflon or glass fibre insulation for up to 760°C

BSWS: For bearing sensor wires, to prevent oil migrating along the leads.

HD: A high-density, swaged wire feedthrough mounted in a sealing gland. For thermocouples, RTDs in validation mapping of autoclaves, pharmaceutical freeze dryer or lyophilizer.

Spares and Accessories

RSC: Replacement sealants can be purchased to allow gland body re-use. For PG, MHC, MHM, PL, TG, Split Glands.

RPS: Replacement packing sets include all the replaceable inner parts for MHC, MHM, PL, TG, Split glands.

Sealing gland lubrication kits: Glands are factory lubricated. If the gland is cleaned or re-assembled it should be re-lubricated with the same lubricant. Kits include lubricant and a convenient one use applicator.

Contact Us