Mineral Insulated Thermocouple (MIT)

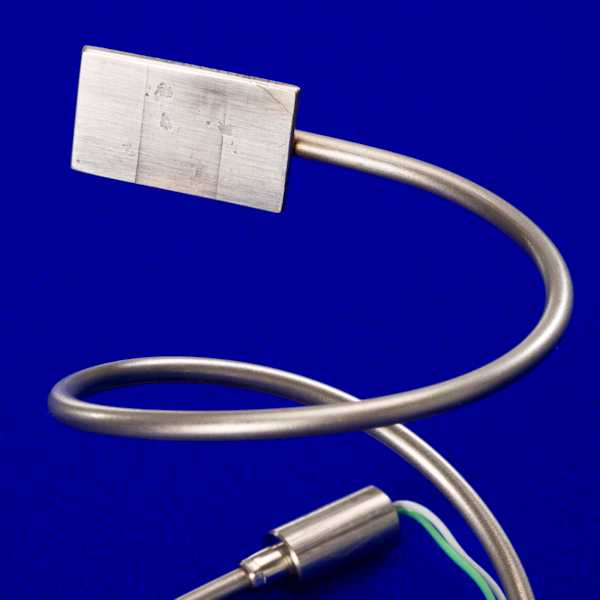

Mineral insulated thermocouples are useful in applications where high temperature resistance, a degree of flexibility and long probe lengths are key requirements. Probes can be bent to allow placement in difficult to reach locations. Examples of applications are chemical process plant, industrial furnaces and kilns.

Completed thermocouples are constructed from lengths of mineral insulated cable (MICC). This consists of thermocouple wires encapsulated in a mineral insulated (MI) core of Magnesium Oxide, inside a soft annealed metal skin.

Mineral insulated probes can be specified in a range of metals, specified in any length, and are available in a wide range of diameters, both Imperial and Metric.

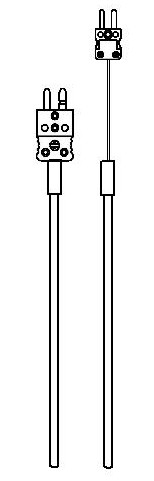

Mineral insulated thermocouples can be purchased with a wide range of process connection fittings, termination arrangements (plugs, heads) and temperature transmitters to ensure the MI probes can be easily integrated into the process.

See ‘Information’ for options

Product Features

- Flexible sheath material in Grade 316L, Grade 310, Grade 321, Grade 304 stainless steel or Inconel & Nicrobel.

- Available in various diameters from as small as 0.5mm to 10.8mm. 0.25mm is available on special applications. Any length

- Available in thermocouple (all types). For PT100 RTD's see product MIR configuration.

- Single, duplex or triplex sensors (dependent on sheath diameter).

- Reduced and swaged tips available

Configuration Options:

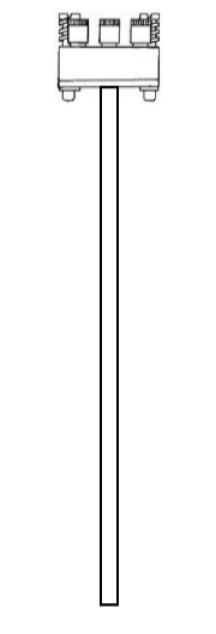

| MIT:

|

|

|

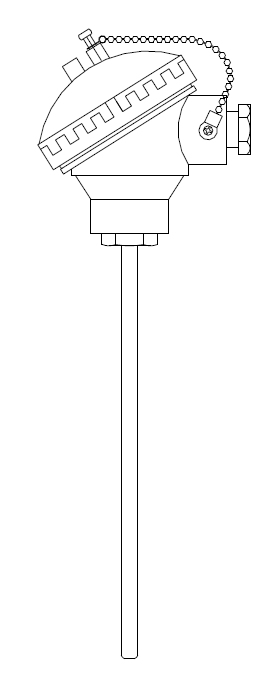

| SLI:

|

|

|

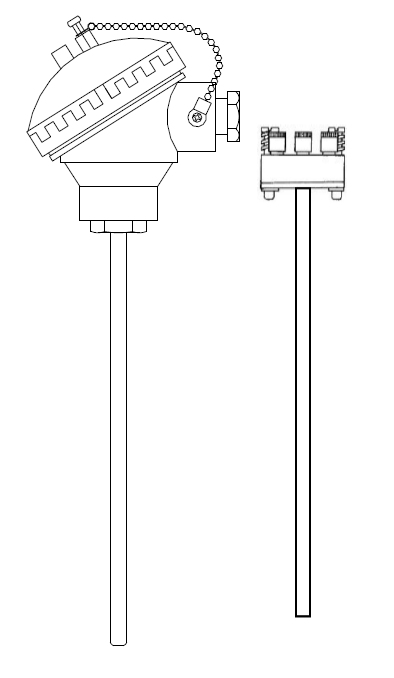

| LD:

|

|

|

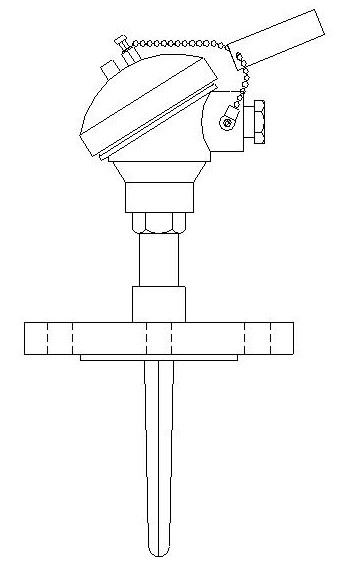

| MD:

|

|

|

| HD:

|

|

|