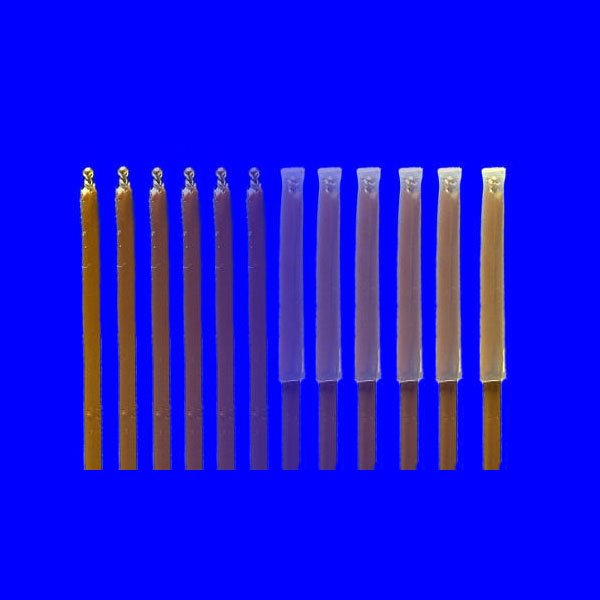

Temperature Validation Thermocouples (VTFP)

Thermal Detection manufactures ready to use pre-cut Type T thermocouples for temperature validation and mapping of autoclaves and similar spaces. The thermocouples are prepared to the customers specification, releasing valuable man hours on site, which allows the validation engineer to concentrate on the critical temperature validation task. As each thermocouple is manufactured in a purpose built factory, using Argon shrouded welding, a high quality thermocouple is assured.

Thermal Detection validation thermocouples are ALWAYS manufactured from material conforming to IEC 60584-1:2013 class 1 material.

They can be specified with Teflon encapsulated tips, weepholes, identification tags and plugs to meet specific site requirements.

A number of type T validation thermocouples can be secured together into a 'loom' to allow easy placement of the thermocouples in the measurement area. Please see our VTFP Loom page.

Please see our useful article on the selection of validation thermocouples here and also our product video below.

Thermal Detection also supplies the full range of thermocouple entry glands and accessories to support all aspects of temperature validation. Please use the product enquiry form to tell us your requirements.

Product Features

- IEC 60584-1:2013 class 1 material

- Conductors Teflon® insulated for autoclaves and lyophilizers, Kapton® insulated for depyrogenation.

- Conductor sizes 1/0.3mm, 1/0.5mm, 3/0.2mm, 7/0.2mm & 13/0.2mm as standard in Teflon®

- Conductor sizes 1/0.3mm & 7/0.2mm as standard in Kapton®

- Formed hot junction either left bare or encapsulated in Teflon®

- Available with a stainless steel protection tip in 316L for hot junction protection and to prevent Kapton® insulation from fraying

- Available with identification at both ends for ease of installation.

- Available with a weep-hole on request

- Available in a wide variety of lengths