How Accurate are RTD’s?

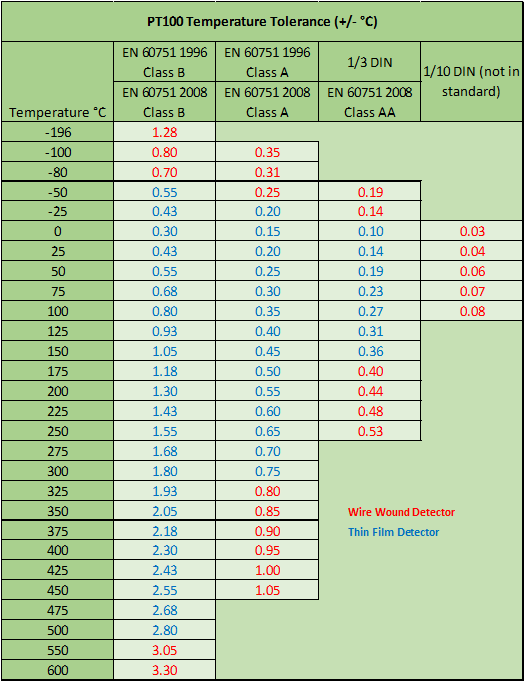

Detectors are commercially available to several different tolerance levels, according to BS EN 60751 as class B, A and AA in order of increasing precision. In addition 1/10 DIN detectors are available which are picked to ensure a tolerance band 1/10th that of a Class B detector.

The table shows the detector tolerance expected at different temperatures, for different classes and also shows temperature limits for thin film and wire wound detectors.

Selecting the right PT100 detector is usually a balance of competing factors. For example, selecting a PT100 detector for use in a pharmaceutical autoclave chamber, it is a balance between the optimum tolerance of the temperature measurement and the resilience of the detector to frequent handling by process operators. It is for that reason that Thermal Detection recommends the use of thin film detectors with a minimum tolerance of class ‘A’ for pharmaceutical applications.

For other applications, such as chemical or manufacturing sectors, Class ‘B’ is often a sufficient level of tolerance. Maximum service temperature may also dictate a ceramic detector in preference to a thin film.

Note that these tolerances apply to the detector before they are incorporated into the temperature assembly. They are a reasonable guide but the true tolerance for the temperature assembly can only be determined by calibration.