What is a Resistance Temperature Detector (RTD)?

A resistance temperature detector (RTD) is a temperature measuring device which exhibits an increasing electrical resistance with increasing temperature. The construction of the detector is such that the change in resistance is predictable and as linear as possible thus allowing temperature to be inferred from the resistance measurement.

The most common material used in an RTD is high purity Platinum. The two main calibration standards are:

PT100: A resistance of 100 ohms at 0.0°C

PT1000: A resistance of 1000 ohms at 0.0°C

The main difference between them is the degree of resistance change over a given temperature change. Other less common standards are also available.

There are two main types of platinum detector:

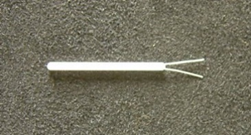

Wire wound sensors.

Platinum wire wound detectors consist of a thin platinum wire loosely wrapped around, or threaded within, a ceramic core.

Wire wound detectors can be used over a wide range of temperatures, up to +850°C, however they can be susceptible to mechanical shock, which induces measurement drift.

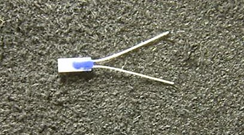

Thin Film Detectors

Thin film detectors are based upon a ceramic substrate with a deposition of high purity platinum, laser etched to give the exact Ohm reading at 0.0°C (100 or 1000). This is then sealed within a glass adhesive. Robust, reliable and low cost, able to operate up to +500°C.

The detectors would normally be incorporated into a temperature probe assembly, see ‘what are the main types of temperature probes?’ above.